CAA Precision Technology Co.Ltd.

Precision Dirves Progress !

Smart Precision for a Smarter World!

ABOUT US

CAA Precision is a specialized engineering partner dedicated to high-complexity CNC machining. While we operate as a boutique agency, we maintain full operational control over a strategic network of ISO-certified manufacturing facilities.

Unlike traditional trading companies, we offer 100% Transparency: We welcome clients to audit our production lines in DongGuan anytime. You get the flexibility of a dedicated project team combined with the heavy-duty capacity of a 50,000 sqm facility. One point of contact, zero communication gaps, and German-standard quality control.”

Adhering to a philosophy of innovation, quality, efficiency, and humanity, CAA Precision aims to evolve from a traditional hardware supplier to an ODM assembling finished products. The company looks forward to collaborating with customers, valuing their trust as the driving force for progress.

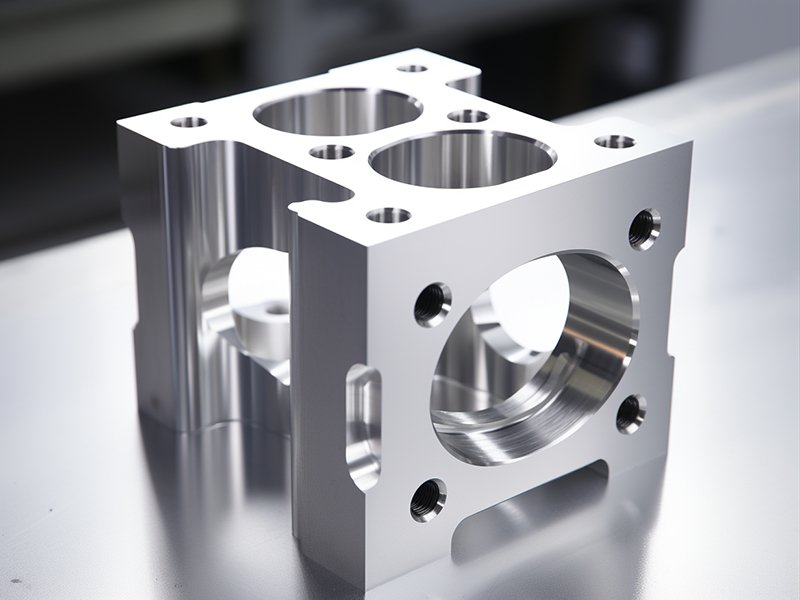

Specializing in precision shaft cores, worm/screw rods, turning parts, machining center components, and hardware production, CAA Precision serves automotive, medical, consumer electronics, fiber optics, hydraulic, and transmission industries. The company provides customer-oriented one-stop services from design to production, delivering cost-saving solutions and striving to be a trusted development partner.

19 years of Industry experience,

300 pieces of equipment,

50,000M²+ of factory space.

Precision Machining for Critical Industries

With extensive expertise in serving the medical and automotive sectors, we specialize in manufacturing high-precision components for demanding applications. Our proven track record includes delivering complex, tight-tolerance parts for surgical instruments, diagnostic equipment, and life-saving devices, as well as performance-driven components for engines, transmissions, and safety-critical automotive systems. Leveraging advanced machining technologies and rigorous quality control, we transform your most challenging designs into reliable, industry-compliant solutions. Trust our experience to meet the stringent standards of these mission-critical fields.

Core Processing Technology

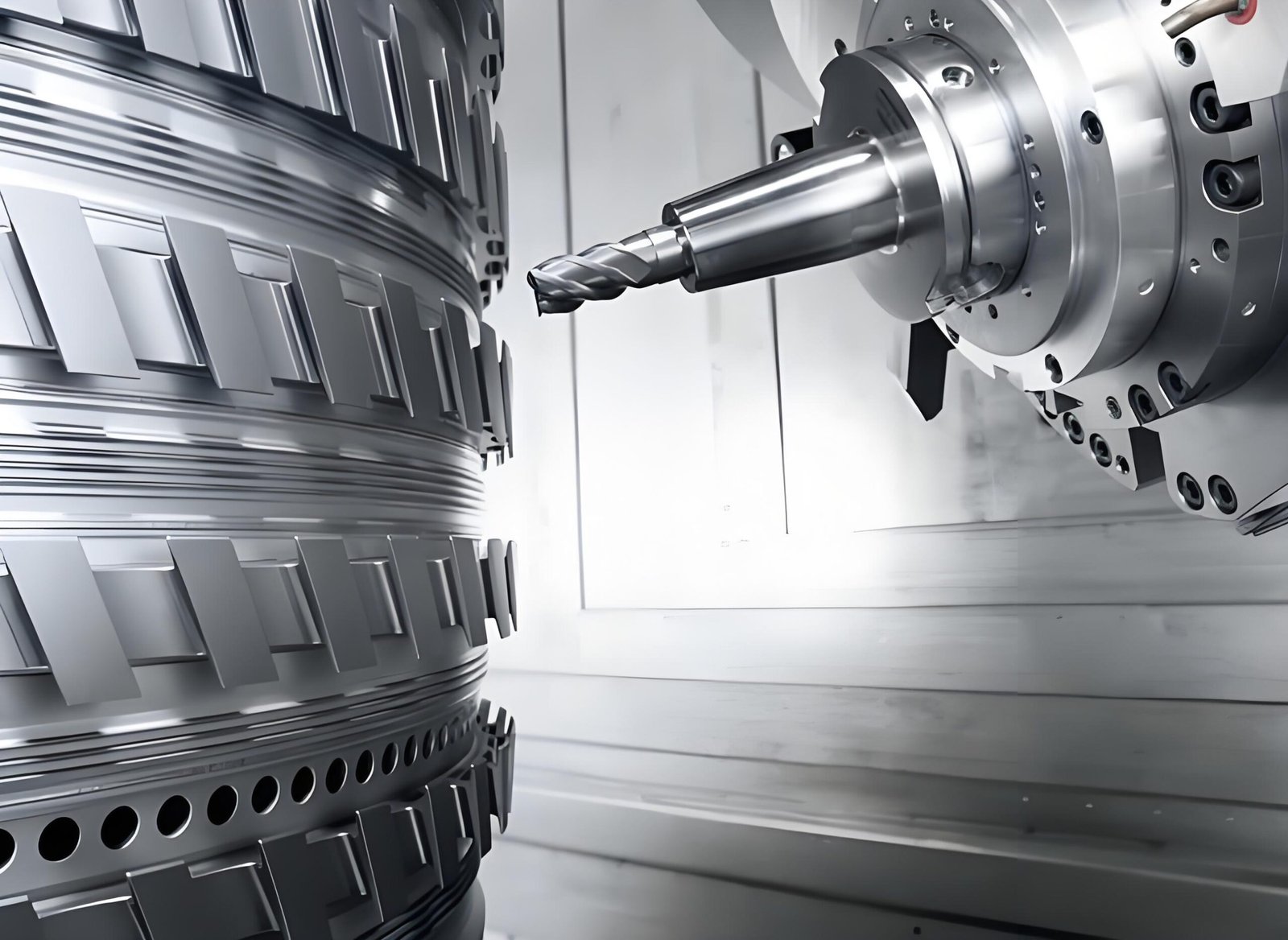

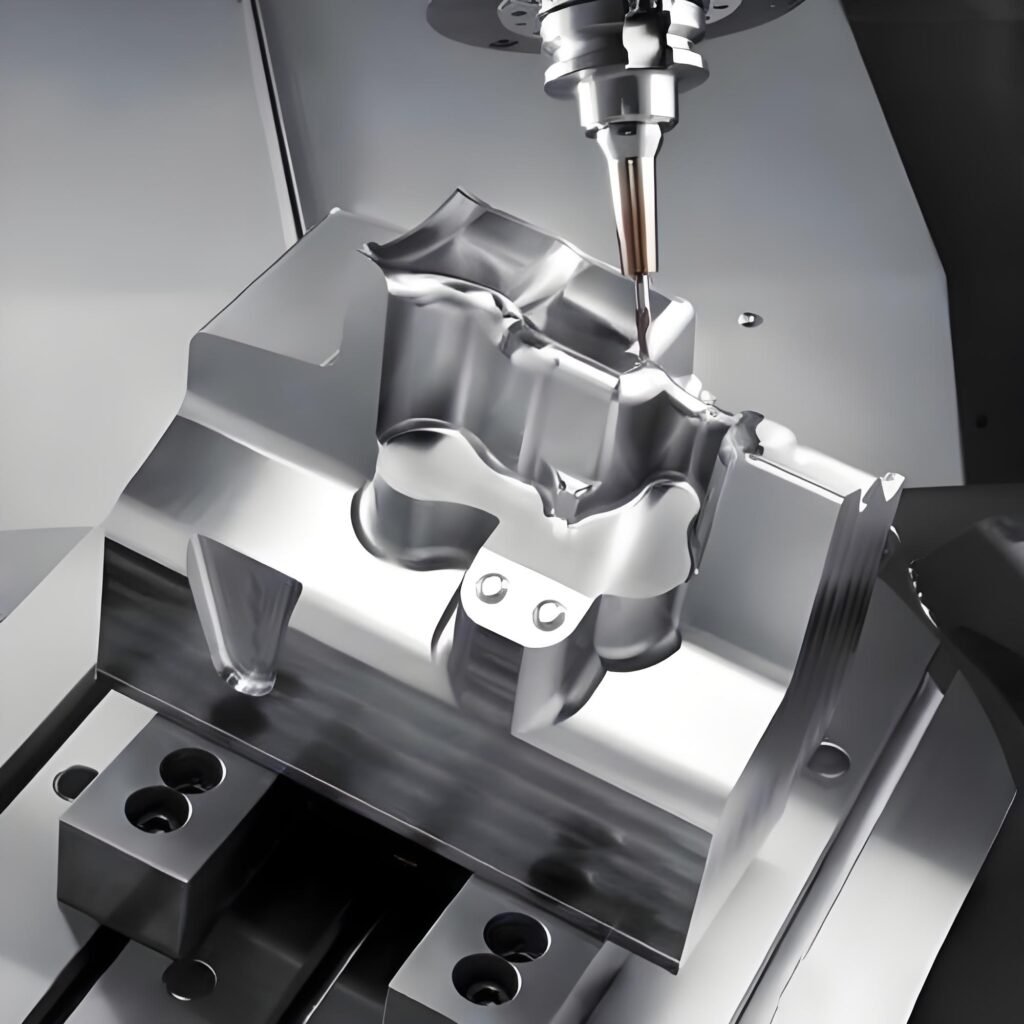

CNC Milling

Milling is a machining process of using rotary cutters to remove material from a work piece. Milling is one of the most commonly used processes in the machining industry today.

Super finishing, creates a cross-hatch pattern on the work piece. An abrasive is rotated in one direction while the work piece rotated in another, creating a cross-hatch pattern.

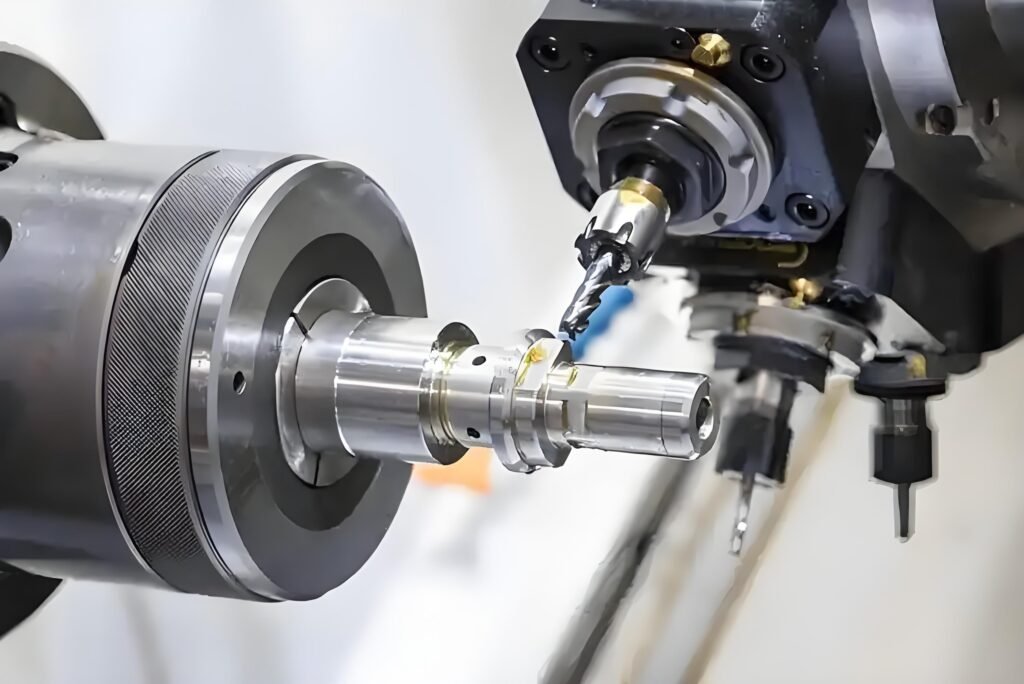

High speed CNC lathes with automatic turret and part catcher for medium-high volume items. Larger items with lower volumes, we utilize conversational programming lathes to meet demand.

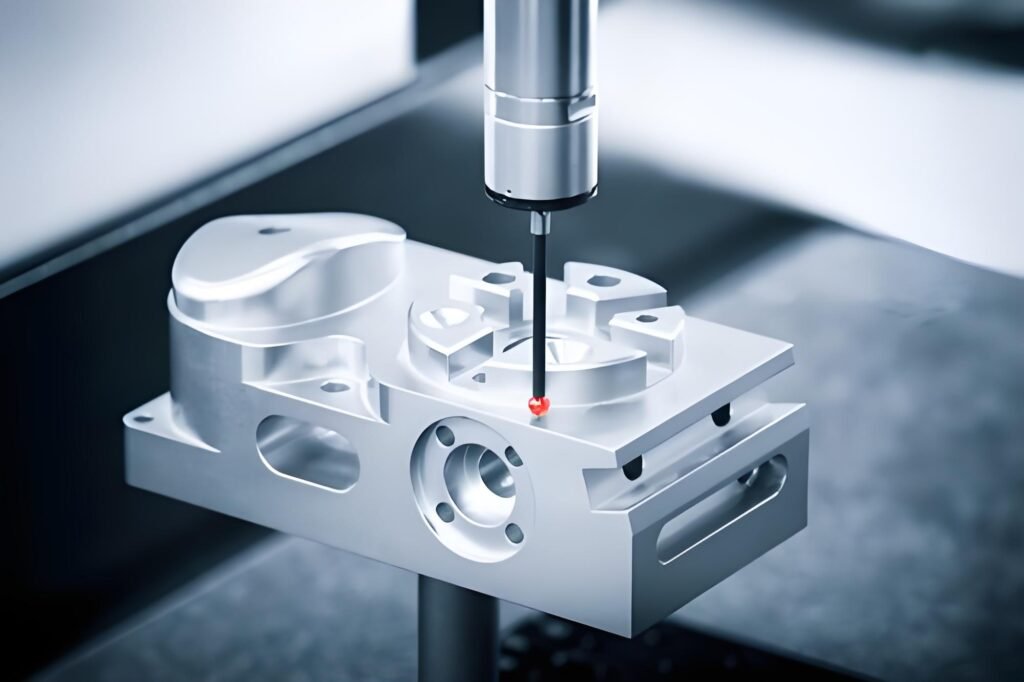

To ensure quality products are going out our door, CAA Precision, Inc. utilizes many different methods for ensuring manufactured parts are meeting customers tolerance as per print.

Multi-tasking in the manufacturing industry is the art of performing various operations without manual intervention. Parts are produced using multiple setups all in one machine.

We use state of the art engineering software to produce 2D or 3D drawings of the project in mind. Provide us with an idea, verbal description, a sketch or completed design and CAA Precision will work with you to produce the high quality pieces you’re looking for.